CLOSE

CLOSE

Xeros Technology 03.11.12

Opening Our Doors To Industry

This year Textile Exchange selected us as one of the exclusive partners invited to host a field trip, running in conjunction with their annual conference. So, last Friday we opened our doors here at Xeros Technology HQ and welcomed into the business sustainability specialists and decision makers from some of the apparel industry’s leading organisations.

Our team of experts hosted a range of engaging activities including workshops, lab scale experiments and live technology demonstrations. The aim of our day was to provide a platform to ask questions, share insights and encourage essential discussions.

Accelerating Change, Together

For those of you who are unfamiliar with their work, Textile Exchange are global non profit organisation, aiming to accelerate the sustainable production and consumption of textiles. Established in 2002, they are known for bringing together various stakeholders across the fashion, textile, and apparel industry and for driving positive environmental and social impacts.

Their annual conference is one of the largest global events for leaders and experts across these industries and this year had over 13,000 attendees. The event was a space to collaboratively explore solutions that will help the industry align with Textile Exchanges Climate+ strategy, which aims to reduce carbon emissions by 45% by 2030. In order to do this, the conference focused on a number of impact areas including; responsible sourcing and production practices, policy and advocacy, transparency and traceability and innovation.

In support of the three day conference hosted in London, Textile Exchange gave their members the unique opportunity to attend field trips, hosted by a few select members.

Education, Innovation and Advocacy

We hosted a field trip which looked at how we can reduce the Impact of Materials as they move into Tiers 1 & 2.

With our science team leading the day, we looked at how chemicals are present in every step in the textile production process, from fibre creation to the finished garment and how this chemistry profoundly alters the building blocks of materials. We know that because of this, selecting materials can a complex and multifaceted challenge for the industry. There are many considerations to be made and we wanted to provide a day which would hopefully help industry understand some of these grey areas in more depth, while giving them a chance to leverage our knowledge on these topics and areas of expertise.

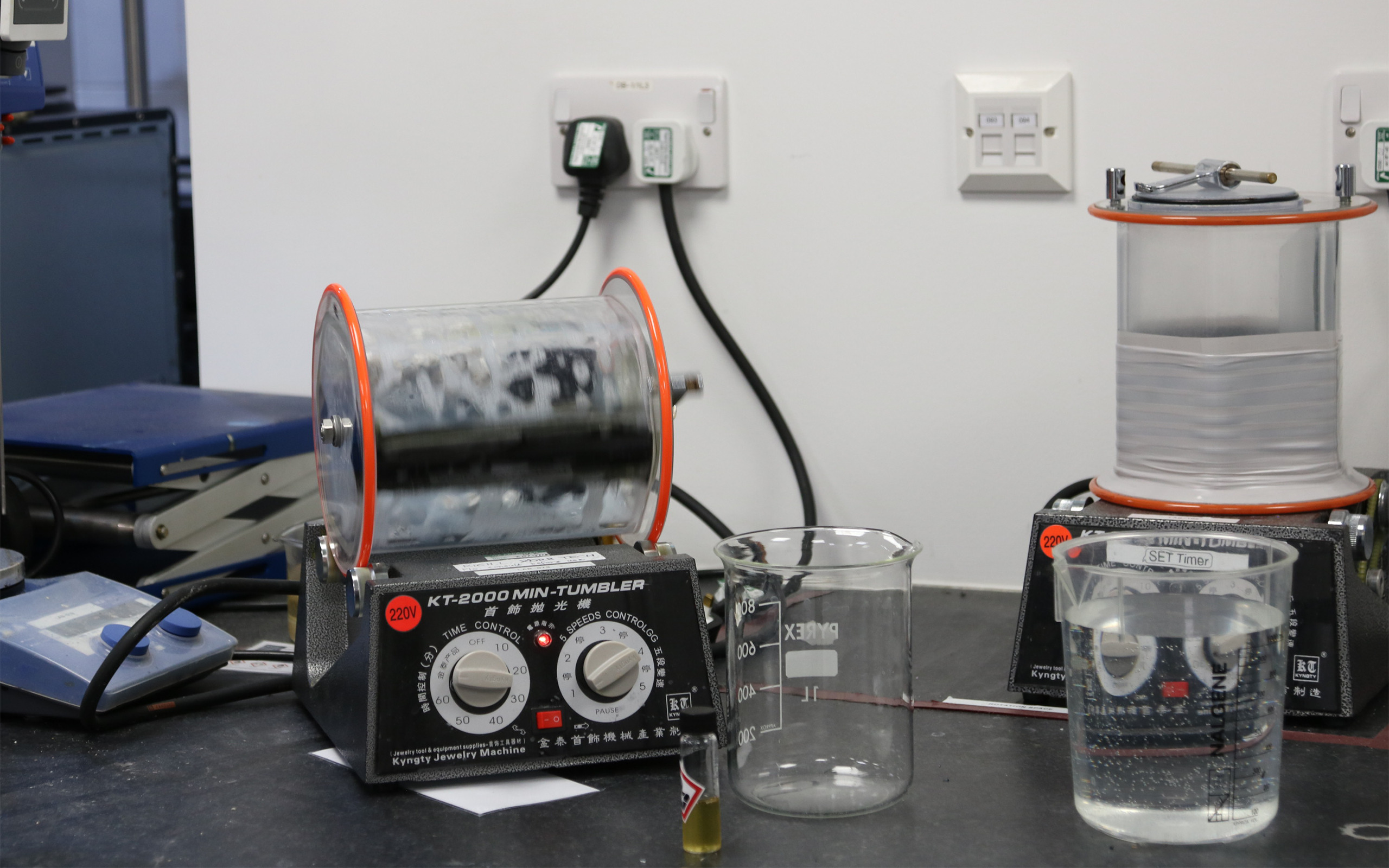

Our science team led a tour covering off three interactive sessions: Material Degradation at End of Life, Microfibre Shedding & Mitigation Strategies, and Applying Chemistry to Materials.

Session One

Robert Bird, our Science Coordinator here at Xeros Technology led the session in our lab on material degradation and end of life, sharing insights on the lab scale experiments he has been conducting. Rob showcased four textile samples of the same fiber group, that had been placed in simulated real world conditions with an enzyme. The experiment was demonstrating differing degradation rates and showed varying speeds of decomposition due to the differing chemicals used during manufacture. This sparked lively and varied conversations on how we can predict the impacts of chemicals at end of life, while ensuring products are designed and manufactured for performance and purpose.

Session Two

Sophie Levine our research scientist and Alasdair Scott our Filtration product owner, encouraged the group to investigate differing fibre types under the microscope and talked to the challenges of microfibre pollution and the impacts of both cellulosic and natural fibres in the environment. Pre prepared samples from four different washing machine loads were of particular interest, as you could visibly see the microfibres released into effluent water from as little as one wash. The most shocking of these samples was an extract form a typical weeks worth of washing, showing large quantities of fibres released into effluent. The team also ran live demonstration of our filtration technology and discussed the upstream and downstream solutions needed across the industry to successfully tackle pollution at scale.

Session Three

Rowan Hunt our denim consultant and specialist, took the attendees through some of the steps that take place in wet processing. Rowan looked at the implications these steps can have on both product and environment, from analysing pumice slurry and contaminated stonewashing effluent to testing the strength and durability of denim products after such processes. Rowan also talked the attendees through our XFN technology which helps to reduce the impact of many of these processes in denim finishing.

Elizabeth Abercrombie, an analytical chemist here at Xeros Technology, with a specialism in green technology, ran a series of demonstrations in our lab including a live demo of a fixed vs unfixed dyeing process. The test analysed some of the potential benefits of applying chemistry to textiles and opened a nuanced discussion on how to make considered decisions for the lowest possible net impact.

Finally, Emily Axten our marketing director and George Harding Rolls of Eco Age, covered off broader topics including upcoming legislation that will affect the textile and apparel industry and the crucial need for need for scaling innovation to help meet ambitious climate targets.

Reaching the Tipping Point

Alongside the educational content provided, we walked our guests through our technology portfolio and talked to the multitude of benefits they can provide along the product life cycle. We are always blown away by the response we get to our technologies and are pleased to say we have created further advocates for our brand and all we stand for here at Xeros Technology. We are confident we sparked some fruitful conversations between our experts and industry and would like to thank everyone who attended the session and made it possible.

One day we will create a tipping point in the industry where sustainable choices become norm and green innovation overtakes outdated methods. Only with ruthless ambition and collaboration will we collectively be able to drive that change.

Keep scrolling for more snap shots from the day…