CLOSE

CLOSE

06/11/24

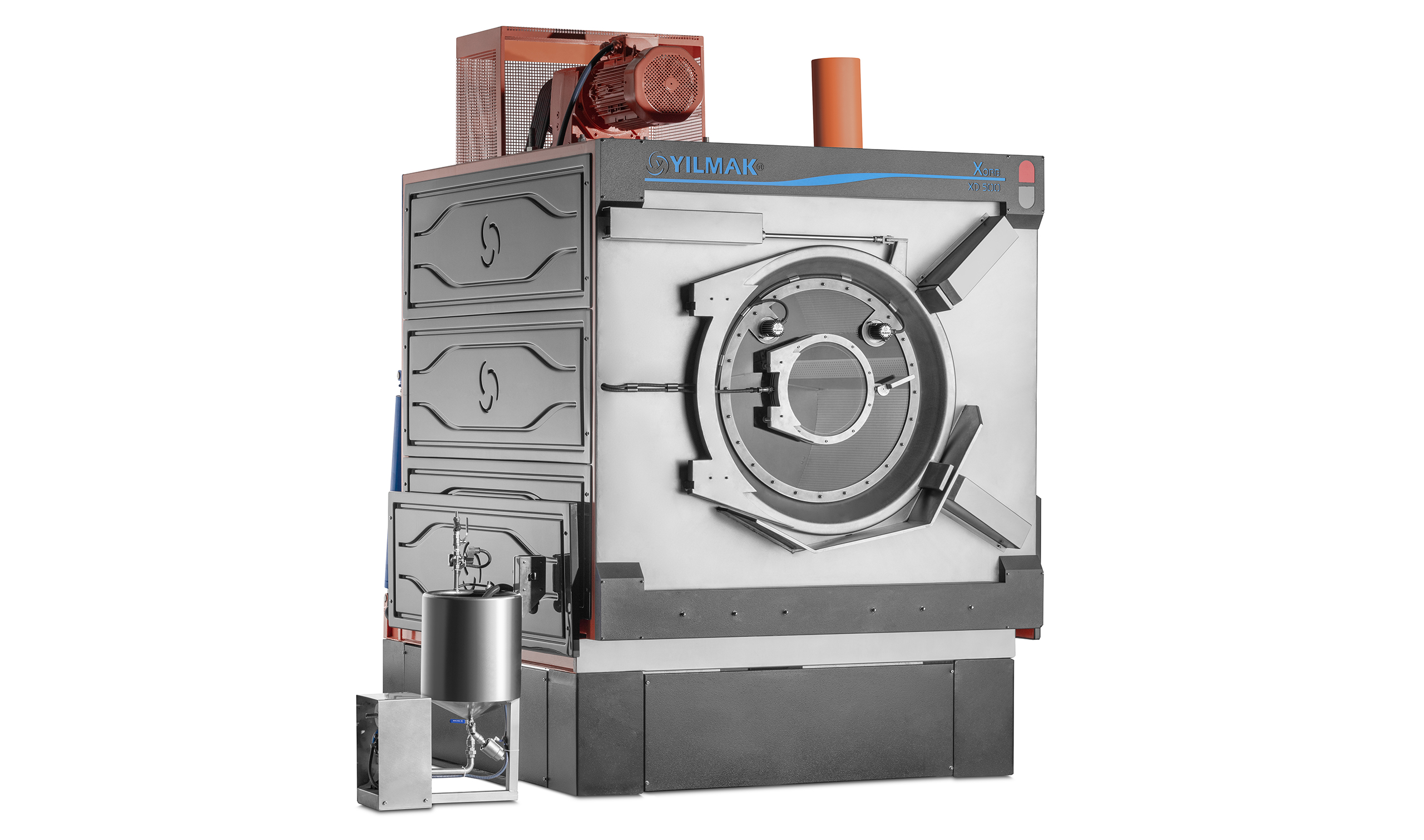

In an era where sustainability is no longer an option but a necessity, XEROS and YILMAK Makina, one of the world’s leading garment finishing manufacturers, partnered in 2023 to change the face of denim finishing. Their groundbreaking collaboration integrates XEROS’ patented XOrbs™ and XDrum™ technology into YILMAK’s machines—creating in a new wave of eco-friendly denim production.

Denim production, especially the finishing process, has historically relied on large amounts of water, energy, chemicals, and pumice stones, which contribute to both waste and pollution. While pumice stones have been essential in giving denim its unique finish, the environmental toll has been significant. With XOrbs™; specially designed polymer beads that can replace traditional pumice, reducing the usage by 100% and significantly reducing the toxic sludge associated with traditional methods.

What are XOrbs™ and XDrum™?

At the heart of our finishing technology are XOrbs™, a durable, reusable polymer bead that works in conjunction with XDrum™, an advanced drum design optimised for water, chemical, and energy savings. By minimising friction and maximising efficiency, these technologies achieve the same denim finish with far fewer resources up to 50% less water is required for denim finishing, all while reducing energy consumption and the chemicals involved. A cleaner, more efficient process that significantly reduces the environmental impact.

The Partnership with YILMAK

YILMAK has been a leader in the denim industry since the 1960s, driving innovation continuously. Through its collaboration with XEROS, YILMAK now offers sustainable solutions without compromising on quality or efficiency. Neil Austin, CEO of XEROS, said: “The apparel industry is under increasing pressure from both consumers and legislators to reduce its impact on the planet. We are pleased to partner with YILMAK to bring our technologies to the global market.”

Furkan Civelek of YILMAK highlighted the partnership’s benefits: “Using XOrbs™ in our Xeros-enabled finishing machines allows us to cut down on pumice stone use while reducing chemical waste and water consumption, leading to significant savings for our customers and a greener planet.”

The XFN Xeros Garment Finishing technology is set to redefine denim finishing by minimizing water and energy use while still delivering the premium finish that manufacturers and consumers expect.

The Environmental Impact

The positive effects of this partnership go beyond just saving water and energy. By using fewer pumice stones, the toxic waste that comes from traditional denim finishing is greatly reduced. Pumice stones break down over time, creating waste that can harm land and water. With XOrbs™, manufacturers can achieve the same great look without these negative effects, leading to less waste and a cleaner environment. Furthermore, using less water and energy not only helps save money for manufacturers but also fights against climate change. The fashion industry is known for its impact on the environment, and by using this new innovative technology XEROS and YILMAK are setting a new example for the industry.

Looking Forward to the Future of Denim

The collaboration between Xeros and YILMAK is more than just an innovation; it represents a significant step toward a sustainable future for the fashion industry. With increasing pressure from consumers and regulators for eco-friendly practices, this partnership can help denim manufacturers stay ahead. This collaboration ensures a future where sustainability, efficiency, and high-quality production coexist, making denim manufacturing cleaner and more responsible.