CLOSE

CLOSE

INVENTING THE IMPOSSIBLE

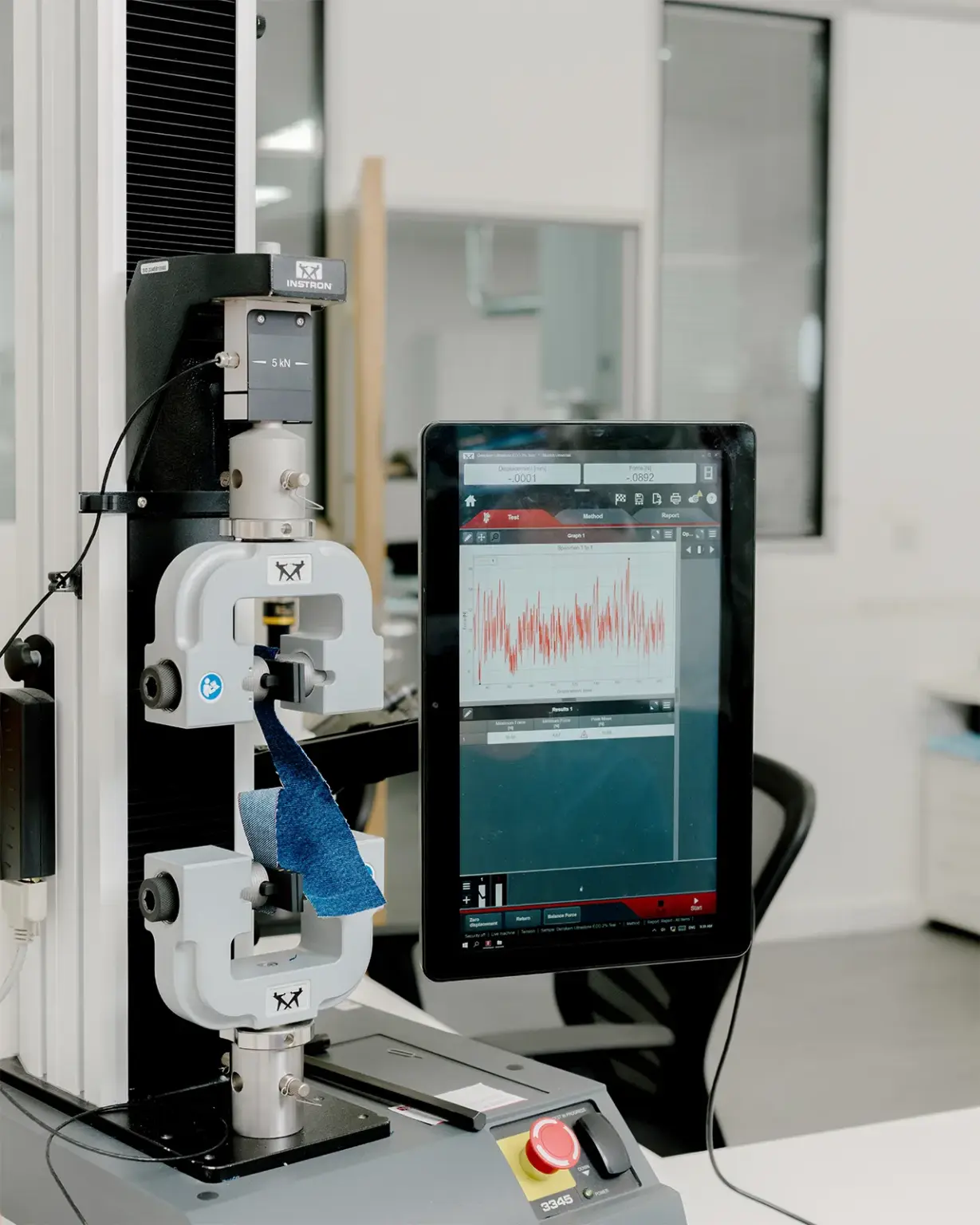

The origins of Xeros Technology began as a research project at the University of Leeds in the textile department. As Xeros Technology has evolved, innovation has stayed central to everything we do and we continue to develop technologies built to advance performance and responsibility. Fascinated by finding new solutions, experimentation and innovation, we believe in relentlessly questioning what we know and exploring new frontiers and emerging technologies. Research begins with our scientific team, who then work together with our engineers and product developers to turn these ideas into real-world, planet-first technologies.

Scroll to read more about the current innovations in our lab, and partnering with us on R&D research.

Textile Applications

The complexity of the fashion industry makes it a challenging problem to solve. Its products and supply chains connect millions of people all over the world. Reported to be a significant contributor to the problem of climate change, it must take its share of responsibility.

The industry is already beginning to make change, led by the pioneers that can imagine a better way. New material innovations, advances in technology, new production methods, and digital solutions are starting to scale.

Our current focus at Xeros Technology is to scale and commercialise the three core textile technologies that we have developed, whilst we continue to evolve these platforms for other applications within the industry. Currently we are exploring industrial microfibre filtration within apparel production, as well as evolving our finish technology for both garment washing and dyeing to reduce water and chemistry.

It isn’t possible to do it alone, so we welcome the opportunity to collaborate with those that also see a better tomorrow. Get in touch if you have a project you’d like to discuss with us.

XFuel

XFuel is a lab-scale initiative, looking at increasing the efficiencies in the production of bioethanol, a sustainable and renewable alternative to fossil fuels.

Bioethanol can be created by the enzymatic hydrolysis of cellulosic materials such as cotton, paper, and agricultural waste. Our hydrolysis method adds a special ‘ingredient X’ to the process which improves the yield and reduces the amount of enzyme required. The introduction of this sustainable special ingredient has shown a 40% reduction in enzyme loading in the lab.

We are now in the process of sharing this innovation with the bioethanol industry to find partners with which we can scale our innovation. We welcome collaboration, please get in touch if you’d like to partner with us.

The Next X Project

Climate change is upon us. As we look to tomorrow we must continue to invent solutions that reduce environmental impact and protect our eco-system.

Our team are already looking ahead, pioneering new ideas that could incite transformation in industry and enable a movement towards a world where both people and the planet thrive.

We are dedicated to the future. By working together we can make a difference.

XEROS TECHNOLOGY. TO THE POWER OF CHANGE