CLOSE

CLOSE

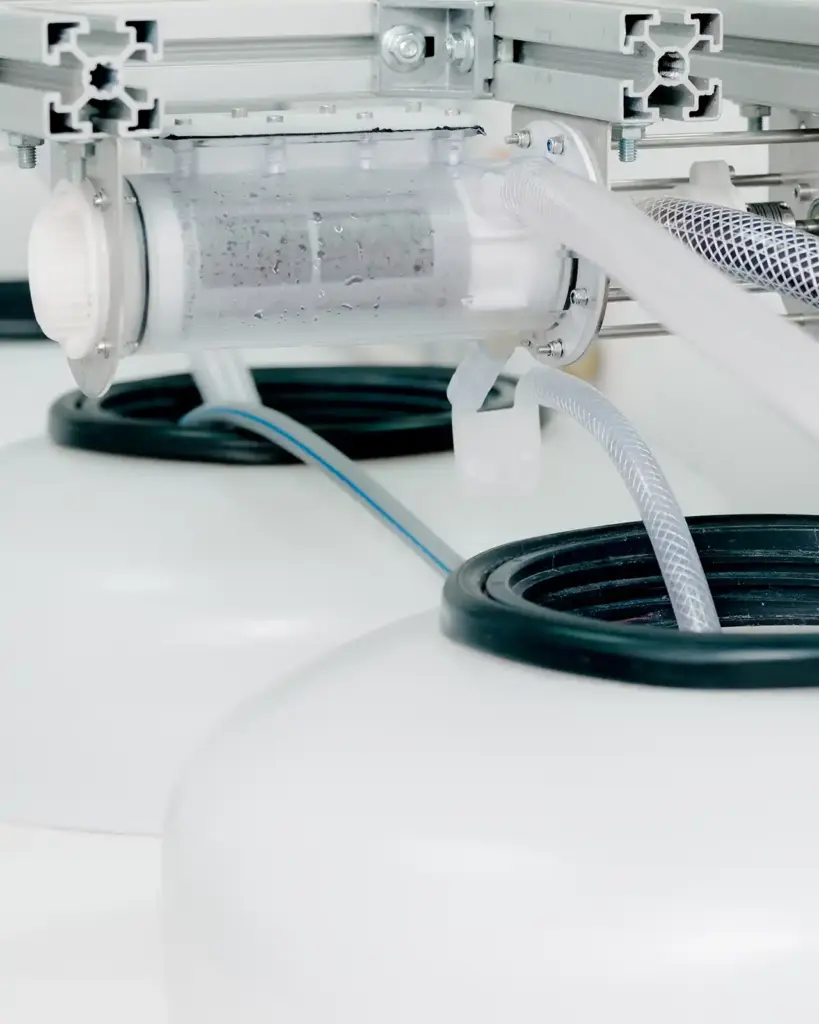

industry leading filtration technology

Xeros Technology in-house lab tests correlate with academic and institutional testing

Research shows synthetic textiles are now the biggest source of microplastic pollution in our oceans. Even on an eco-setting, one load of washing can release thousands of microfibres into wastewater, which go on to contaminate the natural environment.

In 2017, our team of scientists and engineers identified microfibres as an invisible issue that needed to be solved and began creating a filtration technology. Multiple designs and prototypes were invented, tested and improved and XFilter progressed from a theoretical concept to a real life solution.

Our goal was to create a top performing, high-capture filter that would meet consumer needs and be suitable for manufacturers to fit into washing machines. It needed to have the lowest life cycle impact on the planet and last the lifespan of the appliance. The XFilter was designed to need no replacement filters and can be fully recyclable at the end of its life. But fundamentally it needed to be capable of capturing as many microfibres as possible to stop this pollution at its source.

Verified Performance Testing

To validate our high-performance criteria, Hohenstein2, one of the world leaders in textile testing and innovation, carried out an independent study to analyse the retention capacity of microplastics by washing machine filters.

Established over 75 years ago and headquartered in Bönnigheim, Germany, Hohenstein specialises in the testing, certification and research of textile products. They have been at the forefront of microplastic research3 since 2016 and together with the University of Leeds4 and other members of the textile industry, are contributing research members of the Microfibre5 Consortium (TMC) – a research-led sustainable textiles NGO with a vision to work towards zero impact from fibre fragmentation from textiles to the environment.

The 2022 study analysed the retention rate of defined synthetic microfibres (microplastics) using an XFilter device that had been integrated into a 10kg capacity washing machine. The parameters of the washing process were set up to simulate a home washing machine – an easy care program at 30°C with a cycle time of 1 hour 56 minutes was selected. Flock – man-made microfibres cut to the same length, in this case, 0.5 mm – were used as the wash load to imitate synthetic clothes such as fleeces and sportswear. Flock is commonly used in lab testing as it’s repeatable and consistent whereas garment-released microfibres are variable. Garments with varying fibre content can release different quantities of microfibers. This even includes different batches of the same garment bought in the same store. Modern washing machines can adapt the amount of water used in a wash and the length of a cycle, depending on the weight of a load. This can significantly impact the number of microfibres released. It has been reported6 polyester materials shed 161 ± 184 mg of microfibers per kg of textile per wash whereas nylon materials shed 27 ± 16 mg of microfibers per kg of textile per wash.

Retention measurements were performed using two test methods; Dynamic Image Analysis (DIA) and gravimetrical determination. Both methods measured the number of microplastics released into the effluent – the wastewater which flows into our drains.

Dynamic Image Analysis (DIA) – Hohenstein’s preferred testing method – is the most recent and advanced particle characterisation technique. DIA characterises particles in motion by digitising photographs of each particle and storing them in an image file. Each particle is measured in real-time, while the software calculates morphological parameters based on the known size and location of the pixels in each image to enable the testing of particles suspended in water. In this study, DIA was used on the effluent after the flock had been trapped by XFilter.

The results from three wash cycles were:

Cycle number |

Number of fibres used (fibre/l) |

Number of fibres remaining (fibre/l) |

Filter performance (%) |

| 1 | 1,088,482 | 28,240 | 97.4 |

| 2 | 1,163,579 | 2,866 | 99.8 |

| 3 | 1,244,936 | 1,775 | 99.9 |

Gravimetrical determination – the method used by the University of Leeds, The Microfiber Consortium and our science team – is a widely used quantitative approach for accurately determining mass measurements. Calculating the weight gives an understanding of the loss of microfibres from the textile. The most important thing is to capture as high a mass as possible, as microfibres that reach the ocean will fragment into smaller and smaller pieces as part of degradation.

Three wash cycles were tested and the flock that was not captured by XFilter was weighed.

Cycle number |

Mass of fibres used (g/l) |

Mass difference (g) |

Filter performance (%) |

| 1 | 0.1261 | 0.0012 | 96.8 |

| 2 | 0.1238 | 0.0002 | 99.5 |

| 3 | 0.1281 | 0.000 | 99.9 |

As shown by both tests, the first cycle often has a lower retention rate. This is because as XFilter captures more and more microfibres, they start to act as an additional barrier for the other microfibres. In a real-world setting – if washing only synthetic garments – XFilter only needs emptying approximately every 30 washes.

Method validation from different tests is an integral part of the R&D process at Xeros Technology as it ensures quality, reliability and consistency. The reliability of different test methods are discussed further in Tiffin et al. (2021), Reliable quantification of microplastic release from the domestic laundry of textile fabrics7 , published by the Journal of the Textile Institute.

Dr Paul Servin, Group Director of Applications Development at Xeros Technology

“Having two validation methods both accrediting XFilter with the highest level of performance allows us to talk transparently about what our technology can achieve. We selected Hohenstein as our testing partner due to their high-quality testing standards and award winning research on microplastics.”

An earlier model of XFilter was rated as the most effective microfibre filter in a 2020 study by the University of Plymouth8. The study compared the efficiency of six different devices, ranging from prototypes to commercially available products. These were split into two groups, “in-drum devices” which include washing balls and washing bags and “external filters” which included filters either attached to the outside of the washing machine or inside the washing machine drawer, like XFilter.

Scientists washed three different fabric types (100% polyester, 100% acrylic, and a 60% polyester/40% cotton blend) to represent a typical mixed load with predominantly more synthetic fibres. This is a key difference from the Hohenstein study which tested purely synthetic microfibres.

Synthetic clothing comes in many forms, prices and uses and are virtually impossible to avoid. To reduce the impact of synthetic clothing on the environment, the apparel industry needs to take responsibility as a whole. Brands will have the most impact if they take microfibre release into consideration at the design and manufacturing stages. While long term design developments are under way, adoption in mass market is still a way off.

In the meantime, there are simple steps that we as conscious consumers can take.

Interviewed by The Guardian earlier this year, Dr Paul Servin recommends washing garments less often. “Try and consider if the garments need washing or if they can be cleaned in other ways.” He also suggests washing garments in a full load of laundry as this can reduce microplastic shedding by up to five times. Other small changes to the way you do your laundry can help too. Using a liquid detergent and lower water temperature, switching to a front-loader washing machine and, instead of tumble drying your clothes, hanging them out to dry are steps we can all take. As well as washing machine filters, there are also laundry balls and laundry bags that help prevent microfibre pollution. These are in-drum devices that are available to buy today.

Being aware of how we consume clothing is also key. As well as extending the life cycle of a garment, shopping second hand also helps reduce microfibre shedding. Data from our scientific tests show that a new garment may shed as many as eight times more microfibres than the same garment after five washes. After that, microfibre release stabilises at a much lower level. The most sustainable clothes are the ones you already have in your wardrobe.

At Xeros Technology, we believe that microfibre filtration in laundry has a substantial and near-term impact, proven by this independent performance accreditation. Stopping microfibre release from laundry would provide the apparel industry time to develop effective, interdisciplinary solutions across the whole garment life cycle.

1. J. Boucher, D. Friot. International Union for Conservation of Nature. Primary microplastics in the oceans: an evaluation of sources. 2017.

2. Hohenstein – Textile Expertise. To the Point. – Hohenstein

3. Quantitative microplastic analysis – Hohenstein

4. Textile Technology | School of Design | University of Leeds

5. The Microfibre Consortium

6. The role of Textiles in Microfibre Pollution Ocean Wise Science Feature. Research_MicrofibersReport Prepared by Katerina Vassilenko, Mathew Watkins, Stephen Chastain, Anna Posacka and Peter S. Ros.

7. 2021, Lucy Tiffin, Alice Hazlehurst, Mark Sumner & Mark Taylor. Reliable quantification of microplastic release from the domestic laundry of textile fabrics.

8. 2020, Napper et al: The efficiency of devices intended to reduce microfibre release during clothes washing – Science of the Total Environment.7

9. A New Textiles Economy: Redesigning Fashions Future, 2015. Ellen MacArthur Foundation